Rubber machinery made of tradition

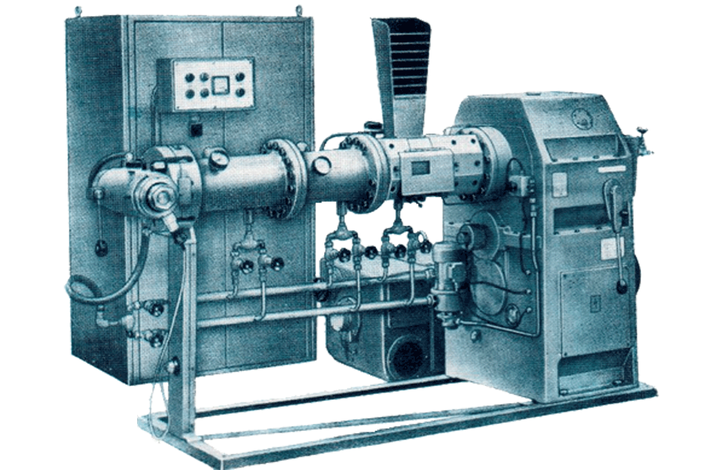

rubicon Gummitechnik und Maschinenbau GmbH, is an acknowledged specialist in the production of extrusion lines for the rubber and silicone processing industries.

Our expertise lies in the development, design and manufacture of top quality extrusion equipment for the cost-effective production of high quality industrial and medical rubber and silicone products, as well as products in the tyre and cable industries.

Thanks to our decades of experience in rubber processing, we create innovative plants customized to the materials and product used by our customers and their processing methods. We support our customers from the initial concept through development and all the project phases right up to the commissioning of their customized plant- and beyond that as well. We supply extruders, extrusion plants, extrusion dies, vulcanization plants, downstream equipment, laboratory equipment and automation solutions to companies all over the world.

The background of our company dates back as far as to the 80s of the 19th century when the company by the name of Schirm KG was established in Leipzig/Germany, a company that produced its first rubber extruders as far back as in the 1930s.

Shortly after their expropriation in the 1970s and their integration into the state-run company VEB Elast- und Plastverarbeitung Halle, Dr. Christian Köhler, who is the Managing Director of this company today, joined the organisation to work here as a development engineer.

The company that produced rubber processing machines exclusively for the former GDR / DDR was closed down by the Treuhandanstalt trust agency shortly after the German Reunification.

In October 1991, Christian Köhler and three partners took a chance on a fresh start and established rubicon. What started out as a pure engineering firm turned into a manufacturer in 1992 when the company bought and rehabilitated an old industrial building.

The quantum jump came in the mid-90s with the development of new machines. Now, the company had found its niche through specializing on customized solutions and special-purpose machinery.

To expand the manufacturing capacity of the company, a new pre-cutting and prefabrication workshop was built in 2004.

In January 2009, a new production hall was commissioned. With a length of 66 meters and a width of 20 meters, this is the largest expansion in the history of this mechanical engineering company.

Deutsch

Deutsch

Français

Français

Español

Español

русский

русский